The F10A Boring Machine has been designed for standard and large capacity Automotive machine work. The spindle diameter is larger than that of the F9A. It has been increased to 3.25" (8.2mm) for extra heavy duty machining up to a 9" (230mm) bore size. Large sleeve cuts can be taken at high spindle rpm's, and in many blocks, one pass sleeve cuts are possible, which increases productivity.The massive one piece meehanite, stress relieved, precision machined base of the F10A model allows the fixturing of large diesel blocks such as Cummins 855, Detroit 12V71, Mercedes 44V12 and odd jobs such as gear cases and connecting rods.The F10A machine can also handle small jobs down to 1.5" (38mm) bore diameter with optional cutterheads. Floor-to-floor bore a V8 block in 15 minutes. Bore through a 6" (152.4mm) bore 4" (101.6mm) in diameter in 35 seconds, .250 sleeve cuts are not a problem. Tooling is available from 1.500 to 9 inches in diameter. Straight through and blind hole boring tools are available. Precision ball screws on the feed give the ultimate feed control.

Brand: Rottler

Model: F10A

Type: Automatic Boring and Sleeving Machine

Control: Automatic CNC

Touch Screen - 4.5” (114 mm)

Spindle Travel (Vertical) - 15” (381 mm)

Workhead Travel (Horizontal) - 50” (1270 mm)

Table - Size - 54" x 21" (1370 x 530 mm)

Travel - Spindle Nose to Table - 26” (670 mm)

Spindle - Rotation Speed - 100 to 1200 RPM

Spindle - Motor - 3.3 HP 2.5kW HP

Bore Capacity (with Optional Cutterheads) - 1.5" - 9" (38 - 228 mm)

Feed per Revolution:

Programmable Feed Rates - .001" - .012"

Programmable Feed Rates - .025 - .300 mm

Electrical Requirements - 208-240V, 30A, 50/60Hz, 1Ph

Air Requirements - 1 cfm @ 90 psi 28 l/min @ 6 bar

Dimensions - Machine - 45” D x 61” W x 80" H

Dimensions - Shipping - 78D x 93W x 93" H

Machine Weight - 4,500 lbs

** The F10A can be programmed for Cylinder length and saved for each of your blocks. This one will not move hole to hole automatically it's a manual hole to hole operation. The F10X is a automatic hole to hole machine with base price without tooling @ $104.947.00.

Block Clamp Arm - set of 2 (Part# 502-1-30)

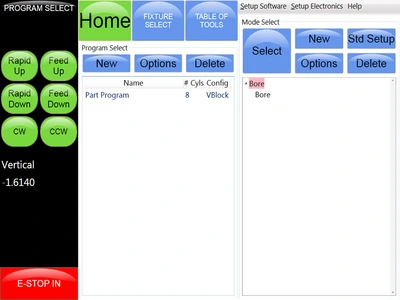

CNC Touch Screen Control, Windows Operating System with Intel Processor

Internet connection to the machine computer must be provided for training support and service.

Automatic Vertical Cycles for Cylinder Boring, Resleeving and Counterboring

Programming and Machine Operation thru extra bright touch screen.

Electronic Handwheel for manual operation in .001" (.01mm) or .005" (.125mm) increments per Handwheel Detent

Precision Digital Readout, .0001" (.002mm) Resolution

Spindle Travel by Precision Ball Screw & AC Servo Motor - Infinitely Variable

Vertical Movement - Z Axis - Up and Down - 15" (380mm)

Spindle Rotation by AC Servo Motor - Infinitely Variable to 1200 RPM

Machine Workhead Floats on Air Cushion for Precision Centering controlled from the Touch Screen - Total Travel - Left/Right Direction 50" 1270mm

Heavy Duty Spindle 3.25" (82.5mm) Diameter with Inner Precision Angular Contact Bearings supported in Adjustable Outer Bearings

Quick Change Cutterhead System

Control:

The F10A Boring Bar is programmed and operated through CNC Touch Screen Control on a Windows Operating System with Intel Processor. Instant Internet Support is available direct from machine. The electronic handwheel provides Manual Operation with two modes. In coarse mode, each "click" of the handwheel will move the machine exactly .001" (.01mm) and in fine mode, each click will move the machine exactly .0001" (.002mm). The pulse hand wheel allows you to feed .0001 per click or .001 per click. The LED reads the actual vertical position in .0001.

Speed - All FA Boring Bar models have the same high performance AC servo motor. Independent feed control allows you to change the feed rate from .001" (.025mm) to .012" (.3mm) per revolution.

Accuracy - The FA series uses a precision ground ball screw to control feed rate and cutter position. This allows the machines to repeat cutter position accuracy to .0002" (.005mm).

Strength - The Rottler proven spindle and bearing design gives you a rigid machine capable of making heavy sleeve cuts for a lifetime. The F10A has increased spindle size to ensure the best possible bore geometry at high spindle speeds.

Flexibility - With variable feed rates you are able to maximize the performance of the machine. Increase spindle feed rates for simple oversize bores. Decrease feed rates for sleeve cuts or counter bores. The F10A machines can bore from 1.5" (38mm) to 9" (230mm). Special carbide tools are available for counterboring, chamfer cutting, offset boring, and O-ringing.

Reliability - The F Series machines use a high-speed, cogged belt drive system. This and the use of two independent motors to run the spindle speed and feed, entirely eliminates the gear box.

Cost Savings - The high speed Rottler FA Boring Bar series machine can bore a block in half the time that other boring machines require. New insert technology is producing long lasting, inexpensive inserts which are capable of handling these high speed and feed rates, with the same cost per insert as previous styles. Inserts do not require sharpening and the low cost of these tools makes them the ultimate choice for boring cylinders.

FOB Seattle WAFormal Quote with Freight Cost and Installation and training Costs upon request.

We use cookies to improve your experience. Privacy Policy.